Our Core Services

Design Engineering

MSM Mechanical has a team of talented mechanical design engineers with years of experience is fabrication design, equipment design, machined parts design, sheet metal design, conveyor systems, and custom equipment design. We utilize proven strategies or develop custom solutions.

Solidworks Design

Design Build Capability

CAD/CAM Design

MRP system enabled

Welding and Fabrication

After parts are laser cut or machined according to engineered specifications our talented team of welders and fabricators add the finishing touches. Being able to build complex equipment or systems to field specified standards is critical for many industries, and our team delivers.

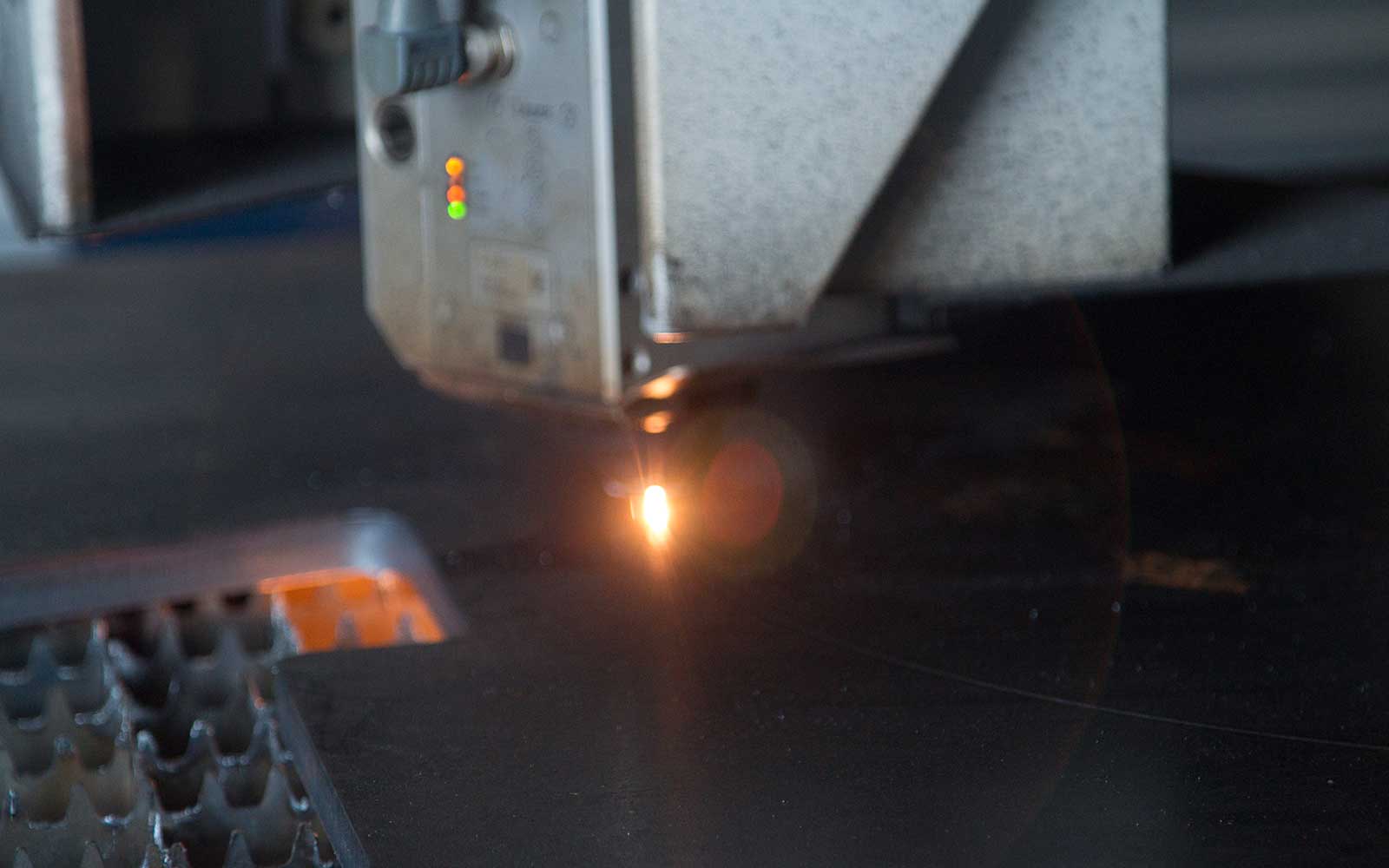

Machining and Laser

Our manufacturing facility is equipped with the latest in technological equipment including laser cutting and CNC machining centers. Our parts manufacturing department collaborates closely with engineering to utilize 3D design direct to the production floor.

Millwright Installation

At MSM we not only provide the latest in manufacturing for industrial solutions but we maintain a talented team of millwright installation crews that are MSM employees. Having our own internal crews means the coordination between engineering and manufacturing is transferred directly to the installation at your facility.

About Our Manufacturing Process

Laser & Machining

-

Laser

We utilize the latest in Laser Cutting Technology up to 2″ thick material. All laser cut patterns are supplied by our engineering department for accuracy.

-

Machining

Our CNC machining centers are the latest in technology provides speed, accuracy, and integration with our engineering department for a more integrated CAD/CAM environment.

-

Brake & Shear

While in today in our modern fabrication facility the laser does the heavy cutting. Our Brake & Shear department is the integral next step before welding operations.

-

Saw & Cut

All bar and tube stock is prepared for fabrication and cut to length prior to welding and fabrication can be completed for structural members.

Welding & Fabrication

-

Carbon Steel

We have a complete black iron welding and fabrication facility for mild steel projects. We coordinate will local powder coating suppliers when needed.

-

Stainless Steel

We have highly qualified stainless fabricators for a quality sanitary finish for food grade specifications.

-

Aluminum

We utilize Aluminum often in designing due to the strength and weight properties. When needed we will provide anodizing services for a finished appearance.

-

Plastics

We use plastics in a variety of ways in fabricating equipment, it’s wear properties are an advantage over lubrication which make it a natural option.

Assembly & Electrical

-

Assembly

We provide a complete assembly process of all manufactured equipment, conveyors, structures, platforms, or custom design build projects.

-

UL Electrical Panels

MSM provides electrical panel services and machine wiring for our projects as required. In some cases we will contract with local electrical groups when warranted.

-

Factory Acceptance Testing

We conduct a variety of FAT’s or Factory Acceptance Test depending on your needs. FAT levels can be defined at the Scope Development Phase.

-

Crating & Shipping

It’s pretty customary but worth noting that we take care of all your crating and shipping needs to insure proper and safe delivery to your facility.

Freight & Parcel Transportation

At MSM we have long served the freight and parcel industry with custom conveyors, including mergers, sorters, divergers, along with various other automation projects.

How do we serve this industry?

-

01

We provide turnkey design build engineered solutions to solve problem areas or as a part of a new facility or upgrade.

-

02

We perform upgrades and installations of large projects including self performing millwright services.

-

03

We provide build to spec equipment or fabrications for replacements performed at the plant level.

-

04

We provide ongoing support with replacement parts manufacturing for maintenance department repairs and needs.

Oil & Gas Manufacturing

Given our proximity to the Oil & Gas Industry we have developed and number of longstanding relationships supplying this industry.

How do we serve this industry?

-

01

We provided engineered and fabricated solutions for a number of industry suppliers and producers in the region.

-

02

We manufacture pre-designed and engineered skids to specification or assemblies required for production.

-

03

We provide build to spec equipment or fabrications for replacements parts and service providers.

-

04

We provide ongoing support with replacement parts manufacturing for maintenance department repairs and needs.

Food & Beverage Processing

MSM engineers, technicians, and installers have many years of experience with food industry equipment and production.

How we serve the Food Industry!

-

01

Design Build custom equipment is a specialty of MSM. We love a challenge and the task of solving them in a unique way.

-

02

We provide a variety of conveyor projects for all types of food products including bakery, dairy, meat, prepared foods, and more.

-

03

We provide fabricated assemblies and parts replacement manufacturing for our equipment. We also provide complete engineered upgrades fro custom equipment and machinery.

-

04

Complete installation of food processing lines is something that we specialize in and have many years experience within our crews and supervisors.

Train & Rail Transportation

MSM has served the Rail Industry for many years with custom fabrications that we engineer or are provided pre-engineered.

How do we serve the rail industry?

-

01

This is where you can place additional information on key points about the position, keeping things shorter if possible.

-

02

This is where you can place additional information on key points about the position, keeping things shorter if possible.

-

03

This is where you can place additional information on key points about the position, keeping things shorter if possible.

-

04

This is where you can place additional information on key points about the position, keeping things shorter if possible.

All Industries We Serve

Our experiences across a wide variety of industries benefits our entire customer base. We are able apply findings and best practices from industry to implement in another.

who do we serve?

-

Agriculture

-

Prepared & Frozen Foods

-

Baking & Snack

-

Food & Beverage

-

Meat & Poultry

-

Oil & Gas

-

Energy

-

Environmental

-

Train & Rail

-

Transportation

-

Freight & Parcel

-

Government

-

Construction

-

Architectural

Mechanical Sheet Metal Division primarily focuses on all contract manufacturing and non-food business sectors that we serve.

MSM Food Division was founded to focus directly on the food industries and food sanitation requirements for machinery.