MSM Mechanical

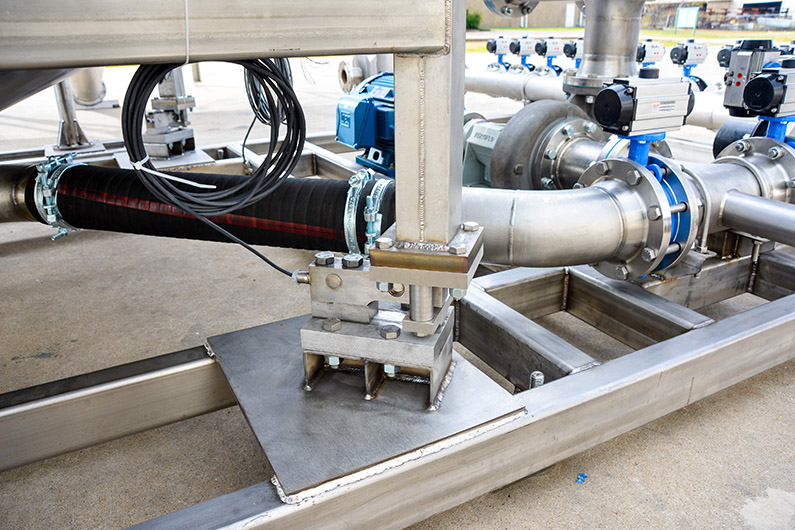

Designed and built liquid mixing systems that deliver consistent results in demanding applications.

Fabrication Under One Roof

Locating a fabrication partner who delivers all services through in-house operations proves to be more complicated than it should be. Most shops talk about capability, then outsource the work they can’t do themselves. The outcome produces various quality discrepancies which lead to project delays and team member disputes about responsibility when errors occur.

MSM Operational Excellence

MSM Mechanical runs its operations through a distinct operational framework. Our company acquired equipment and facility space and hired skilled workers to manage complete projects which start with raw materials and end with finished assembly. When we guarantee a specification, we’re backing work done by our own team on our own equipment.

You Can’t Afford Suprises

This method becomes essential when you create products which will carry your personal brand identity. The frames and tanks and assemblies which you buy from us will become the essential parts of the equipment your customers need. You can’t afford surprises, and neither can we.